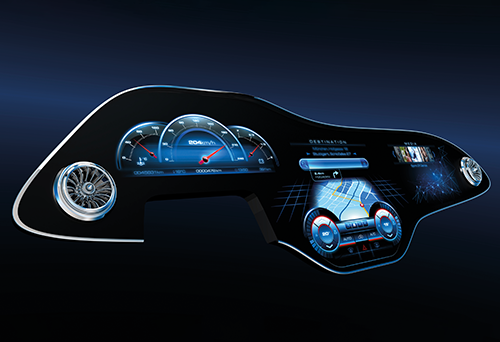

Automotive Display

Displays in cars serve as instrument clusters (IC) or head-up displays (HuD) to show important information to the driver, as central information displays (CID), or as passenger or rear seat displays for entertainment. Sometimes they even replace mirrors and serve as camera surveillance displays. Especially in cars, there are no limits to form factors and 3D shapes. They sometimes have various features such as image enhancement, privacy modes or anti-glare features. All of these displays must be of high quality to withstand significant temperature differences, virbations and shocks and need to display content under changing lighting conditions. They must also be able to be viewed from different angles to accommodate different sizes, positions, and passengers.

Measurement tasks

The German Flat Panel Display Forum (Deutsches Flachdisplay Forum, external link), a leading expert network in the field of displays, has developed recommendations for automotive displays together with the OEM working group. These include specification values and methods for optical tests. They apply to all types of automotive displays. Examples are:

- OEM Specification

- DFF OLED Specification

- DFF BlackMURA

- DFF Gamma

- DFF Sticking Image (3-level)

- Angular OEM Regions

Premium manufacturers in particular have drawn up additional specifications to ensure readability and the highest optical quality. Many of these measurements were devloped, evaluated and/or researched in projects together with TechnoTeam. These include, for example the follwoning measurement tasks:

- Display Sparkle for anti glare layers (AGL)

- Sticking Image (2-level)

- Reflection for contrast under ambient light (sun light)

- Resolution by Pixel Cross Talk

- Resolution by Slanted Line MTF (Modulation Transfer Function)

- Halo for Full Area Local Dimming Display (FALD)

- Any measurement item from a vantage point as e.g. driver and passenger

Our solutions

TechnoTeam offers a wide array of lenses and specialized add-ons to ensure fast and reproducible measurements according to all these requirements and methods. Our dedicated robotic-based ILMD system, the LMK Position - can ensure fast and highly reproducible alignment of various shapes, including ultra-wide screens and free-form shapes common in modern cars. For more information on the specific products and applications, please refer to the dedicated information shown below:

RELEVANT PRODUCTS

RELEVANT PUBLICATIONS

International Display Workshop (IDW 2023)

International Conference on Display Technology (ICDT 2023)

Journal of the Society for Information Display

International Conference on Display Technology (ICDT 2021)

Journal of the Society for Information Display

SID Vehicle Displays & Interfaces 2021

electronic displays Conference 2016

SID Vehicle Displays & Interfaces 2019

This contribution concentrates on the performance of two selected image sticking evaluation methods [5, 6] from the automotive community and [1] for reference. After briefly introducing the three methods, this contribution focusses on their capability of separating initial non-uniformities from the actual sticking image effect of the target display. Therefore, a mathematical analysis, which is based on a simple but physically motivated sticking image model, is performed. Based on that, an additional non-uniformity correction is proposed. This additional correction has a positive influence on the precision but a negative influence on the measurement time of the fastest measurement method [6]. Thus, we propose a workflow, that decides based on the properties of the DUT whether the correction is necessary or not. All conclusions are supported by simulations and validated using measurement results of a randomly chosen non-uniform automotive LC display.

The aim of this paper is on the one hand to quantize the mathematical influence of the methods and on the other hands to suggest a workflow, which utilizes an existing method and optimizes its application with respect to precision and overall measurement time.

SID Vehicle Displays & Interfaces 2018

Based on the general working principle of ILMDs (imaging luminance measurement device), we briefly explain typical ILMD characteristics as well as the concepts of repeatability, reproducibility, precision and measurement uncertainty [1]. Afterwards, optical display properties as well as measurement methods [2, 3, 4] are introduced.

Finally, we qualitatively and quantitatively assess chosen influences of ILMD specifications and different measurement procedures on the obtained results.

Thus, this work shall convey a feeling for photometric display metrology requirements under the consideration of the measurement task and the desired precision