High magnification measurement image of an OLED display

OLED, MicroLED and LED Display

Display technologies such as OLED or MicroLED are constantly improving. They have for instance an outstanding contrast and a large color gamut. Through constant improvements, they are being used in more and more applications, e.g. in televisions, in smartphones and in vehicles and in microdisplays. However, in order to be able to guarantee the high quality of these displays, very special measurement applications have to be carried out in addition to standard measurement tasks, e.g. luminance or color over angle. One reason for this is that, in contrast to LCDs, each display pixel acts as its own light source. In other words, there is neither a global nor a local backlighting unit.

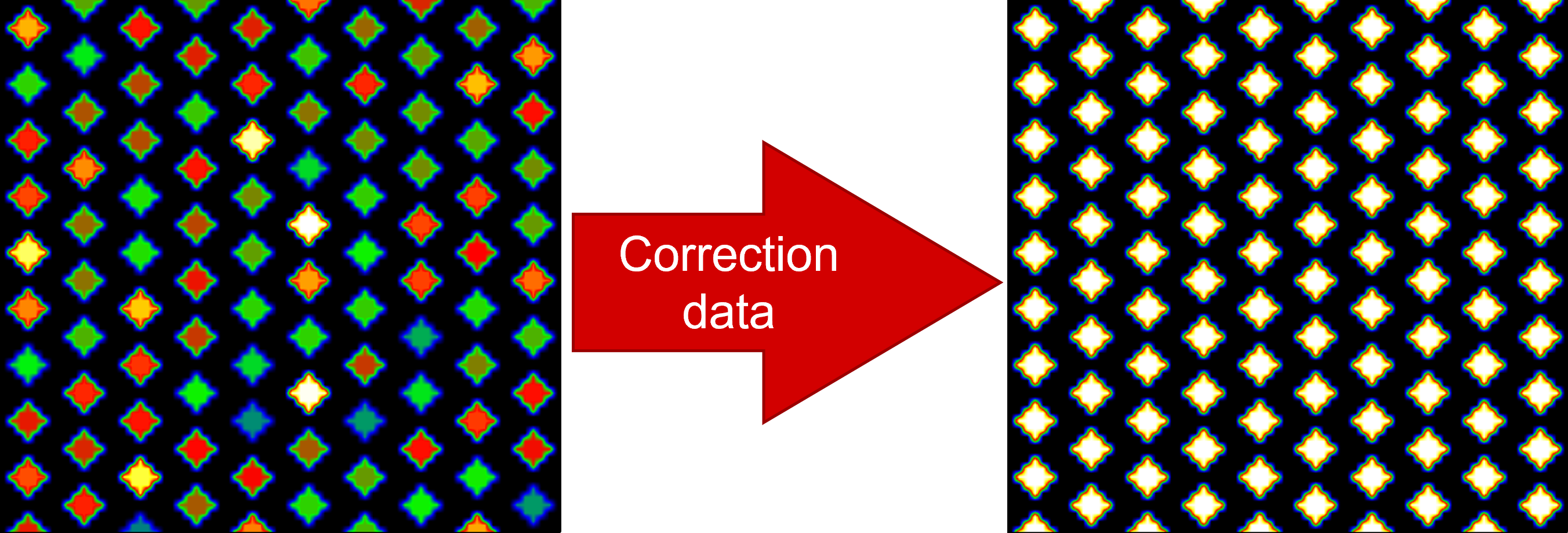

One of this special applications can be the measurement of ghost images. If individual pixels are used more often than other pixels, vanishing image sticking and permanent image sticking may occur. In contrast to LCDs, this can also be color-dependent as different colors are realized by different material systems. Thus, an image sticking measurement should cover all relevant aspects as it might not be possible to repeat the measurement with the same display. Furthermore, the individual pixels can suffer from production-based luminance and chromaticity variations. This can lead to a visible low and high-frequency non-uniformity. In the case of low grey levels, this is also referred to as DeepGreyMura or graininess. The correction of these effects is called DeMURA. It requires a luminance and/or chromaticity value of each subpixel. It might also be required to get this information for different grey levels ans colors. Especially in production, this measurement needs to be very fast.

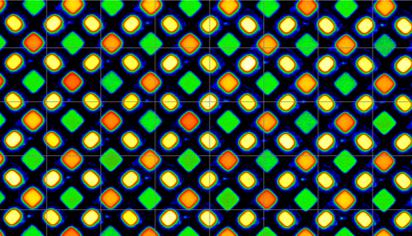

Luminance image based evaluation of an OLED display DeepGreyMura using the high frequency uniformity evaluation "Sparkle"

Concept of DeMURA

Our Solution

Our hard- and software solutions can be used for all standard and specific OLED, LED, and MicroLED-Display measurement tasks. For quality assurance the following LabSoft add-ons can be used:

- Image sticking (vanishing ghost images and permanent Burn-In),

- Sparkle (high-frequency non-uniformity evaluation such as DeepGreyMura or graininess),

- BlackMURA (low-frequency non-uniformity evaluation)

- Conoscopic contrast measurement (low-frequency non-uniformity over angle)

Furthermore, our specialized DeMURA software offers a high-speed measurement solution for pixel-level-luminance measurements in the production.

RELEVANT PUBLICATIONS

International Conference on Display Technology (ICDT 2024)

International Conference on Display Technology (ICDT 2023)

International Meeting on Information Display (IMID 2022)

To ensure a correct pixel registration (assigning the luminance to the correct pixel) in state of the art methods, display pixels are partially switched off [Patent US9135851B2]. However, this reduces cycle time and changes the average pixel level, which can affect the results.

We present a method to overcome these issues, called Advanced Pixel Registration (APR). It is based on a specific registration pattern applied during a teach-in process. An example pattern is provided in Figure 1 (left). After this initial registration, DeMURA measurements can be performed with only one image capture per input signal. The same is true for following displays during EOL testing, as small misalignments, which occur in production control environments as slight shifts, inclinations or rotations of the DUT (see Figure 2) can be corrected automatically.

This contribution validates the APR method using a flat and free-form curved display with methods similar to [] Feng, X. (2019), 78-2: Measurement and Evaluation of Subpixel Brightness for Demura. SID Symposium Digest of Technical Papers, 50: 1122-1125.]. The results show that the APR method can significantly improve the efficiency of DeMURA processes required for high-quality LED, OLED and MicroLED displays, regardless of their shape.